Mondelēz International (Kraft Foods, Inc.)

TŘINECKÉ ŽELEZÁRNY, a. s.

INERGY Automotive Systems Slovakia, s.r.o.

Bekaert Slovakia, s.r.o.

|

Bekaert is a leading multinational company in the field of steel wire processing that employs over twenty-seven thousand people. Bekaert Slovakia with its factories in Hlohovec and Sládkovičov specializes in the production of wire materials for the building industry and tyre cords. The current highly competitive situation on the market poses great demands on production efficiency and thus the company focused on minimizing the downtime of the individual machines. The pursuit of positive employee motivation by the production plant management, for instance by their financial interest in the performance, ran into the lack of information from the operation. The company lacked a tool that would monitor the operating condition of the individual machines in detail and thus allowed unambiguously distinguishing between efficient and responsible workers and those who pull the production efficiency downwards. The objective of the commission was to find a solution that would accurately monitor machine utilization, record and categorize downtimes and also provide employees at various corporate hierarchy levels with corresponding information, all of which without increasing the overhead costs. |

|

|

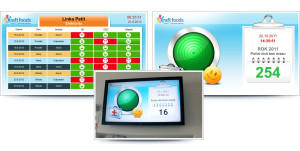

The combination of the EIS System (ELVAC Industry Signage) and InfoPanels, which the client internally calls the VAS System (Visualization Automation System), was selected as the ideal solution. It is designed as an extension and addition of the Database Automation System (internal Bekaert solution) that obtains information about the machines in real time using PLC controllers. Subsequently, VAS collects, processes, sorts out and retroactively provides acquired information in the form of a graphic presentation of the production data from the individual branches of Bekaert Slovakia s.r.o. and Bekaert Hlohovec a.s. The system interface is realized through the ASP.NET website that runs on the IIS platform (Internet Information Services). The proposed solution with the use of the website provides for an easy consolidation into one “portal” and its subsequent use by managing production employees who can monitor current production data, overall equipment efficiency (OEE) and so on directly from their computers using an internet browser. The multi-language reports are used both for displaying in the InfoPanels System (panels in the production, canteens etc.) and for displaying separately on the web for the needs of the managing employees. In addition to production data, the system also displays presentations, latest news, operating changes and informs of the results of competitions, future events and other facts. |

|

Global Business, s.r.o.

DONGHEE Czech

|

The Donghee production plant in Český Těšín for the production of components for passenger vehicles includes a welding plant, two paint shops – cataphoresis and electrostatics, assembly lines, a compressor plant, technical gas evaporating stations and many other divisions. Our Company realized an order for so-called control sheets for the production plant that are used for entering and approving the results of the individual production tasks executed at selected workstations. The results are entered and approved using interactive displays and software based on our long-term knowledge in the field of Digital Signage. Approvals take place on a multi-level basis and the resulting control sheets are provided in both printed and electronic form. The control sheets can be displayed directly on the interactive displays or in applications based on the EIS technology (ELVAC Industry Signage) installed in the computers of medium-level managing employees. |

|

ABB

|

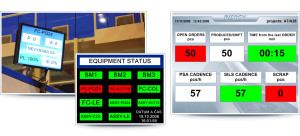

ABB is a leading global company providing technology for the energy industry and automation that allow power engineering and industrial enterprises increase their efficiency while decreasing the impact of their activity on the environment. ABB has 135,000 employees in more than 100 countries. ABB has been operating in the Czech Republic since 1970; it runs its business in eight localities and currently employees almost 3,000 people. Czech ABB has the possibility to use international know-how and the latest R&D results of a global company. It offers an added value to its customers in the form of a strong background of its own engineering and service centres and long-term experience of traditional Czech producers. The main lines of business of ABB are: Energy Industry Products, Energy Industry Systems, Production Automation and Drives, Low-voltage Products and Process Automation. The Brno branch requested a production data presentation using a TV wall located in the production hall. The TV wall was installed using eight LCD screens and it was expanded to sixteen screens four years later. The InfoPanels System displays production data, such as capacity fulfilment, register of produced and dispatched pieces, production plan and so on. The data for the displays are received from SAP systems, Excel files and the corporate Intranet. |